Introduction

Composite materials, a fusion of distinct materials to create a stronger whole, have deep roots that stretch back thousands of years. These materials have revolutionised various industries, from construction to aerospace, becoming indispensable in engineering solutions where strength, durability, and weight savings are critical. As the need for advanced composites grows, understanding their evolution provides insights into the future potential of these materials and, indeed, the future of engineering itself.

The Origins: Ancient Composites

Early examples of composites can be traced back to ancient civilisations. As early as 3,000 BCE, the Egyptians used a mixture of mud and straw to build durable structures that still stand today. By combining the tensile strength of straw with the stability of clay, they created a material resilient enough to withstand harsh desert conditions. Similarly, the Mesopotamians and Chinese developed pottery strengthened with fibres, laying the foundation for the complex composite structures we rely on today.

The 20th Century: Birth of Modern Composites

The modern era of composites began during World War II, driven by the need for lightweight and resilient materials in military applications. Fiberglass was introduced in the 1930s and quickly became a staple in various industries. Aircraft and vehicle manufacturers recognised its high strength-to-weight ratio, enabling innovation in design and functionality.

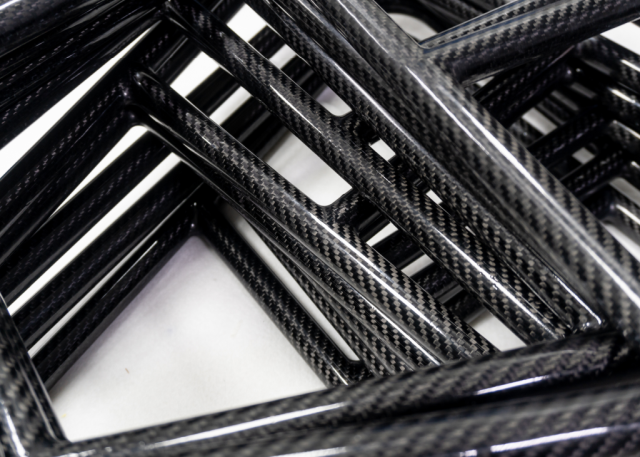

By the 1960s, carbon fibre emerged, further transforming industries. Carbon fibre’s remarkable properties—lightweight, high tensile strength, and excellent fatigue resistance—made it ideal for aerospace applications. NASA and the aviation industry were early adopters, embedding carbon fibre composites into spacecraft and aircraft components that required precision and endurance.

The Present Day: Advanced Composites in Industry

Composite materials today have evolved significantly, with applications that span beyond aerospace to automotive, construction, energy, marine, and medical fields. Carbon, aramid, and glass fibres are combined with matrix materials like polymers, metals, and ceramics to form composites that meet increasingly stringent performance requirements. Notably, the automotive industry has embraced composites to create lightweight yet crash-resistant vehicles, significantly reducing emissions and fuel consumption. In the energy sector, composite materials are indispensable in producing wind turbine blades, which require extreme durability to withstand harsh weather conditions while maintaining aerodynamic efficiency. Similarly, medical devices and sports equipment rely on composites for optimal performance and durability.

The Future of Composites: A Pathway to Sustainability

With an increasing focus on sustainability, the next chapter in the history of composite materials centres around recyclability, bio-based alternatives, and reduced environmental impact. Research into thermoplastic composites, which are easier to recycle, and bio-composites made from renewable sources, such as flax or hemp, demonstrates a precise industry shift toward greener solutions. Innovations in recycling technologies and waste management also pave the way for a circular economy in composites, enabling manufacturers to reclaim valuable fibres and resins for reuse.

Fluency’s Role in Driving Composites Innovation Forward

At Fluency, we understand the intricate dynamics of the composites industry and the unique challenges it faces in today’s fast-evolving landscape. Our deep expertise in marketing for composites and advanced materials enables us to connect companies with the right audiences and amplify their impact in an increasingly competitive market. With insights into the industry’s past and a focus on the future, we help companies position themselves as leaders in innovation and sustainability.

Conclusion

The history of composites is a testament to human ingenuity and the pursuit of excellence in engineering. As we look to the future, Fluency stands ready to support businesses navigating this complex industry, enhancing visibility, and driving growth. For companies committed to advancing the possibilities of composite materials, our team is here to help you communicate your vision to the world.